What Is An Axle? Types Of Axles - SKengineers

WHAT IS AN AXLE?

An axle or axletree is a central shaft for a rotating wheel

or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating

with them, or fixed to the vehicle, with the wheels rotating around the axle.

In the former case, bearings or bushings are provided at the mounting points

where the axle is supported. In the latter case, a bearing or bushing sits

inside a central hole in the wheel to allow the wheel or gear to rotate around

the axle. Sometimes, especially on bicycles, the latter type axle is referred

to as a spindle.

Types Of

Axle -

Axles

come in three standard types -

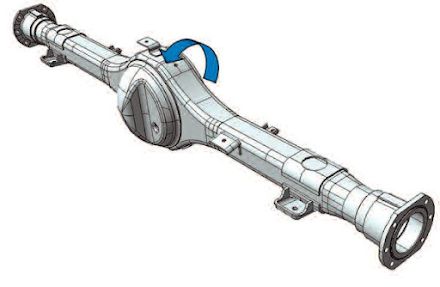

Rear axle -

This axle is responsible for the power supply to the drive wheels. It comes in two halves, called half-waves, which are connected by the differential. In most cases, the rear axles are under tension, meaning that they rotate with the vehicle’s wheels.

Front axle -

This axle is located in the front of the vehicle and is responsible for assisting in steering and processing bumps on uneven road surfaces. They consist of four main parts: the beam, the swivel pin, the tie rod and the stub axle. The front axles must be as robust as possible. That is why they are usually made of carbon steel or nickel steel.

Stub Axle -

Types Of

Rear Axle -

Not all

rear axles are the same, as the support and mounting methods there are three

types of rear axles -

Semi-floating axle -

This rear axle connects the wheel to the flange on the

outside of the axle shaft and holds it securely. One bearing supports the axle

shaft and the other is in the axle housing. Since it has two bearings, a

semi-floating axle must be larger than the other options to produce the same

torque. Semi-floating axles are used for automobiles, SUVs, and medium-sized

trucks, Pickups with half a ton and low power.

Full-floating

axle -

As the name suggests, thanks to two bearings, this type of

axle effectively floats in place and maintains its position. It only transmits

the drive torque. Fully floating axles are best for larger vehicles, e.g. heavy

trucks. Some medium-sized trucks with larger towing capacity or those with

all-wheel drive can also benefit from fully floating axles.

Three-quarter floating axis -

It is more complex than the semi-floating axle and also more

reliable. It helps in maintain wheel alignment and handles side thrust and

driving torque.

Live Axles -

Live axles are used to transmit power throughout the

component. They are responsible for driving the wheels that they are attached

to. Despite being designed as a moving part, some live axles may also be used

to support the weight of the vehicle. When examining a front wheel drivetrain,

live axles are responsible for steering the vehicle. Depending on the vehicle,

some may utilize a live rear axle that is also responsible for steering.

The most common type of passenger vehicles contain live

axles only in the rear of the assembly, while in a four-wheel drive vehicle,

both the front and rear axles are live. Six-wheel drive vehicles contain three

axles which are all live axles.

Dead Axles -

Dead Axles are used solely as a support for part of the

vehicle while providing a mounting for the vehicle's wheel assembly. Typically,

dead axles are found in the front area of commercial trucks and truck-tractors.

Almost all common passenger vehicles lack a front axle, as they utilize

independent front-wheel suspensions. It is uncommon for a commercial vehicle to

rely on a dead axle.

A dead axle is technically not included in the parts that

make up a drivetrain and does not have a differential attached to it, as it is

a free rotating axle that is only utilized when there is a large amount of

weight placed on it. They mount wheels, bearings and even gears in some drive

axle setups.

Dead axles remain in sync with the drivetrain itself and are

crucial for commercial vehicles that utilize them. Despite not transferring

power like live axles do, their importance lies with their responsibility to

carry the wheel itself.

Axle housing cases are manufactured in either a one-piece or

split construction. An axle housing with a split design is commonly referred to

as "banjo housing" by many, as they bear resemblance to a banjo

instrument. Both the front and rear openings of the axle housing are provided

in the center housing. The differential carrier closes the front opening, while

a spherical cover plate covers the rear opening.

It is responsible for carrying the weight of a vehicle and

is typically an extremely heavy component. Heavy-duty trucks and truck-trailers

possess axle housing that is heavier than the housing found in common

commercial vehicles, as they are designed to transport heavy weight.

The axle housing in light-duty trucks may be a combination

of cast iron and cast steel tube. The differential and final drive cases are

generally a cast and machined unit, while the axle housing itself is welded or

extruded steel tubing.

There are several components that may be welded into the

axle housing itself, such as: mounting flanges, braking plates, spring mounting

plates and any accessory units that a mechanic or driver may want to install

into the housing. These components are typically replacement or upgrade seals

or plates that that are installed by a third-party.

Additionally, vents or valves are installed on top of the

housing to prevent pressure from building up, which develops from heat within

the housing. Heat is produced from normal operation of the vehicle, and these

vents or valves release the heat. If the pressure is not released from the

housing, it may force the axle lubricant to move past the rear wheel oil seals

and damage the vehicle's brake linings. Despite allowing air to pass through

the housing, these vents prevent debris and dirt from entering.

Types Of

Front Axle -

There are

vehicles have two main types of front axle -

Dead

Front Axle -

These axles stay in place and don’t rotate with the wheels.

Most dead front axles and differentials have housings that prevent them from

coming into contact with water or dirt.

Live

Front Axle -

Unlike dead front axles, live front axles deliver driving

power from the gearbox to the front wheels.

Types Of

Stub Axle -

As The Engineers Post explains, there are four types of stub

axle -

Elliot -

This type uses a kingpin, a yoke, and a cotter to connect to

the front axle.

Reverse

Elliot -

This type has the opposite arrangement of a standard Elliot

stub axle.

Lamoine -

This stub axle type has an L-shaped spindle instead of a

yoke-type hinge.

Reverse

Lamoine -

It has the opposite layout of a standard Lamoine stub axle.

Terminology

-

On cars and trucks, several senses of the word axle occur in

casual usage, referring to the shaft itself, its housing, or simply any

transverse pair of wheels. Strictly speaking, a shaft which rotates with the

wheel, being either bolted or splined in fixed relation to it, is called an

axle or axle shaft. However, in looser usage, an entire assembly including the

surrounding axle housing (typically a casting) is also called an axle.

An even broader (somewhat figurative) sense of the word refers

to every pair of parallel wheels on opposite sides of a vehicle, regardless of

their mechanical connection to each other and to the vehicle frame or body.

Thus, transverse pairs of wheels in an independent suspension may be called an

axle in some contexts. This very loose definition of "axle" is often

used in assessing toll roads or vehicle taxes, and is taken as a rough proxy

for the overall weight-bearing capacity of a vehicle, and its potential for

causing wear or damage to roadway surfaces.

Structural

features and design -

A straight axle is a single rigid shaft connecting a wheel

on the left side of the vehicle to a wheel on the right side. The axis of

rotation fixed by the axle is common to both wheels. Such a design can keep the

wheel positions steady under heavy stress, and can therefore support heavy

loads. Straight axles are used on trains (that is, locomotives and railway

wagons), for the rear axles of commercial trucks, and on heavy duty off-road

vehicles. The axle can optionally be protected and further reinforced by

enclosing the length of the axle in a housing.

In split-axle designs, the wheel on each side is attached to

a separate shaft. Modern passenger cars have split drive axles. In some

designs, this allows independent suspension of the left and right wheels, and

therefore a smoother ride. Even when the suspension is not independent, split

axles permit the use of a differential, allowing the left and right drive

wheels to be driven at different speeds as the automobile turns, improving

traction and extending tire life.

Axles are typically made from SAE grade 41xx steel or SAE

grade 10xx steel. SAE grade 41xx steel is commonly known as

"chrome-molybdenum steel" (or "chrome-moly") while SAE

grade 10xx steel is known as "carbon steel". The primary differences

between the two are that chrome-moly steel is significantly more resistant to

bending or breaking, and is very difficult to weld with tools normally found

outside a professional welding shop.

How Many

Axles Does A Car Have?

The number of axles in a car depends on the type of vehicle.

In most cases, cars have two axles to turn the wheels. Larger vehicles that

carry more passengers and have more wheels can have more axles.

It’s easy to identify the number of axles your car or other

vehicle has. Just look at your car from the side and then count the pairs of

tires. Most cars have a total of four tires or two sets of tires, one in the

front and one in the rear. Two sets of tires correspond to two axles.

Comments

Post a Comment