What Is Hydraulic Pumps? How It Works? - SKengineers

WHAT IS HYDRAULIC PUMPS? HOW IT WORKS?

A hydraulic pump converts the mechanical energy from the

prime mover into hydraulic energy for use by the system. Hydraulic energy is

the combination of pressure and flow required by the actuators to perform

useful work. It is important to understand that hydraulic energy is both

pressure and flow combined, because one without the other cannot achieve work.

Pressure would just consist of trapped fluid and flow would have no energy to

move fluid alone.

A hydraulic pump pushes on fluid, and in this regard, fluid can be considered a solid as it is transmitted throughout the machine and then pushes on actuators to eventually move loads. Motion control professionals will have me point out that oil is compressible, but that’s a discussion for another blog. The point is that a pump could be pushing on sand, ball bearings or any other solid medium capable of taking the shape of its container, and the result would still be the transmission of force.

Transmission of force is really the name of the game with

hydraulics, and is the basis for Cosford’s Law, which states that “pressure

makes it go, flow is just the rate in which you can create pressure.” For fluid

to be moving, pressure must absolutely be highest at the pump; always. This

flies in the face of the fallacy that pressure is resistance to flow. Pressure

will rise as high as it needs to be to overcome downstream resistance, but if

it didn’t start at the pump, fluid would move backwards.

Pressure in hydraulics is the result of Newton’s Third Law of Motion, that every action has an equal and opposite reaction. The opposing force can be a loaded cylinder or a flow control, and the pump doesn’t care which. It will continue to push the fluid as pressure rises to overcome resistance, even if it results in something blowing up or the prime mover being overloaded.

Flow from a pump is a function of displacement (volume) and

speed. A larger pump can push more fluid at once, or by spinning a pump faster,

it will push on fluid more often. Just like in the world of electrons, where

power is a combination of voltage and amperage, power in hydraulics is a

combination of pressure and flow. By doubling pressure while leaving flow the

same, horsepower is doubled. Also, by doubling flow while leaving pressure the

same, horsepower is also doubled.

Understanding the operation of a hydraulic pump will do

volumes (no pun intended) for your understanding of fluid power. When you

realize all energy starts at the pump, you can better design or troubleshoot

any system.

TYPES OF

HYDRAULIC PUMPS -

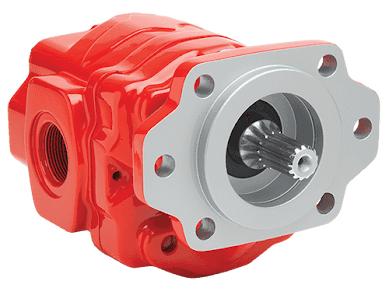

GEAR PUMPS -

For truck-mounted hydraulic systems, the most common design

in use is the gear pump. This design is characterized as having fewer moving

parts, being easy to service, more tolerant of contamination than other designs

and relatively inexpensive. Gear pumps are fixed displacement, also called

positive displacement, pumps. This means the same volume of flow is produced

with each rotation of the pump’s shaft. Gear pumps are rated in terms of the

pump’s maximum pressure rating, cubic inch displacement and maximum input speed

limitation.

Generally, gear pumps are used in open center hydraulic

systems. Gear pumps trap oil in the areas between the teeth of the pump’s two

gears and the body of the pump, transport it around the circumference of the

gear cavity and then force it through the outlet port as the gears mesh. Behind

the brass alloy thrust plates, or wear plates, a small amount of pressurized

oil pushes the plates tightly against the gear ends to improve pump

efficiency.

FEATURES

-

Most common design

Fewer moving parts, easy to service, more tolerant of

contaminates, relatively inexpensive

Fixed, also called positive, displacement pumps

Rated in terms of max pressure rating, cubic inch

displacement, max input speed limitation

Used in open centre hydraulic systems

Transports oil around circumference of gear cavity and

forces it through outlet port

Encompasses thrust plates that push against gear ends with

small amount of pressurized oil to improve pump efficiency.

PISTON PUMPS -

When high operating pressures are required, piston pumps are

often used. Piston pumps will traditionally withstand higher pressures than

gear pumps with comparable displacements; however, there is a higher initial

cost associated with piston pumps as well as a lower resistance to

contamination and increased complexity. This complexity falls to the equipment

designer and service technician to understand in order to ensure the piston

pump is working correctly with its additional moving parts, stricter filtration

requirements and closer tolerances. Piston pumps are often used with

truck-mounted cranes, but are also found within other applications such as snow

and ice control where it may be desirable to vary system flow without varying

engine speed.

A cylinder block containing pistons that move in and out is

housed within a piston pump. It’s the movement of these pistons that draw oil

from the supply port and then force it through the outlet. The angle of the

swash plate, which the slipper end of the piston rides against, determines the

length of the piston’s stroke. While the swash plate remains stationary, the

cylinder block, encompassing the pistons, rotates with the pump’s input shaft.

The pump displacement is then determined by the total volume of the pump’s

cylinders. Fixed and variable displacement designs are both available.

FEATURES

-

Withstand higher pressures

Higher initial cost, lower resistance to contamination and

increased complexity

Additional moving parts, stricter filtration requirements

and closer tolerances

Truck-mounted cranes

Good when desirable to vary system flow without varying

engine speed

Fixed and variable displacement designs available

Encompasses cylinder block containing pistons that move in

and out – this movement draws oil from the supply port and forces through the

outlet

Angle of swash plate determines the length of the piston’s

stroke

Swash plate remains stationary.

Displacement determined by total volume of pump cylinders.

FIXED

DISPLACEMENT -

With a fixed displacement piston pump, the swash plate is

nonadjustable. Its proportional output flow to input shaft speed is like that

of a gear pump and like a gear pump, the fixed displacement piston pump is used

within open centre hydraulic systems.

VARIABLE DISPLACEMENT

As previously mentioned, piston pumps are also used within

applications like snow and ice control where it may be desirable to vary system

flow without varying engine speed. This is where the variable displacement

piston pump comes into play – when the hydraulic flow requirements will vary

based on operating conditions. Unlike the fixed displacement design, the swash

plate is not fixed and its angle can be adjusted by a pressure signal from the

directional valve via a compensator.

Should more flow be required, the swash plate angle changes,

increasing the pump displacement by creating a longer piston stroke. Contrary

to a fixed displacement piston pump, the variable displacement is used in a

closed centre system. With a closed centre system, the swash plate angle within

the variable displacement pump decreases as the flow requirement diminishes so

that there is no excess flow or loss of hydraulic horsepower.

Variable displacement piston pumps can be flow compensated,

pressure compensated or both flow and pressure compensated.

Flow

Compensated –

As flow requirements change, the swash plate angle is

adjusted to maintain a constant margin of pressure.

Pressure

Compensated –

Regardless of changes in system pressure, a specified flow

is maintained through adjusting the swash plate angle.

Flow and

Pressure Compensated Combined –

These systems with

flow and pressure compensation combined are often called a load-sensing system,

which is common for snow and ice control vehicles.

VANE PUMPS -

Vane pumps were, at one time, commonly used on utility

vehicles such as aerial buckets and ladders. Today, the vane pump is not

commonly found on these mobile (truck-mounted) hydraulic systems as gear pumps

are more widely accepted and available.

Within a vane pump, as the input shaft rotates it causes oil

to be picked up between the vanes of the pump which is then transported to the

pump’s outlet side. This is similar to how gear pumps work, but there is one

set of vanes – versus a pair of gears – on a rotating cartridge in the pump

housing. As the area between the vanes decreases on the outlet side and

increases on the inlet side of the pump, oil is drawn in through the supply

port and expelled through the outlet as the vane cartridge rotates due to the change

in area.

FEATURES –

Used on utility vehicles, but not as common today with gear

pumps more widely accepted and available

Input shaft rotates, causing oil to be picked up between the

vanes of the pump which is then transported to pump outlet side as area between

vanes decreases on outlet side and increases on inlet side to draw oil through

supply port and expel though outlet as vane cartridge rotates.

Screw pumps -

Screw pumps (fixed displacement) consist of two Archimedes'

screws that intermesh and are enclosed within the same chamber. These pumps are

used for high flows at relatively low pressure (max 100 bars (10,000

kPa)).[clarification needed] They were used on board ships where a constant

pressure hydraulic system extended through the whole ship, especially to

control ball valves[clarification needed] but also to help drive the steering

gear and other systems. The advantage of the screw pumps is the low sound level

of these pumps; however, the efficiency is not high.

The major problem of screw pumps is that the hydraulic

reaction force is transmitted in a direction that's axially opposed to the

direction of the flow.

There are two ways to overcome this problem:

put a thrust bearing beneath each rotor;

create a hydraulic balance by directing a hydraulic force to

a piston under the rotor.

Types of

screw pumps –

single

end

double

end

single

rotor

multi

rotor timed

multi

rotor untimed.

Bent axis

pumps

Bent axis pumps, axial piston pumps and motors using the

bent axis principle, fixed or adjustable displacement, exists in two different

basic designs. The Thomas-principle (engineer Hans Thomas, Germany, patent

1935) with max 25 degrees angle and the Wahlmark-principle (Gunnar Axel

Wahlmark, patent 1960) with spherical-shaped pistons in one piece with the

piston rod, piston rings, and maximum 40 degrees between the driveshaft center-line

and pistons (Volvo Hydraulics Co.). These have the best efficiency of all

pumps. Although in general, the largest displacements are approximately one

litre per revolution, if necessary a two-litre swept volume pump can be built.

Often variable-displacement pumps are used so that the oil flow can be adjusted

carefully. These pumps can in general work with a working pressure of up to

350–420 bars in continuous work.

Inline axial piston pumps -

axial

piston pump, swashplate principle -

By using different compensation techniques, the variable

displacement type of these pumps can continuously alter fluid discharge per

revolution and system pressure based on load requirements, maximum pressure

cut-off settings, horsepower/ratio control, and even fully electro proportional

systems, requiring no other input than electrical signals. This makes them

potentially hugely power saving compared to other constant flow pumps in

systems where prime mover/diesel/electric motor rotational speed is constant

and required fluid flow is non-constant.

Rotary

vane pumps -

Fixed

displacement vane pump -

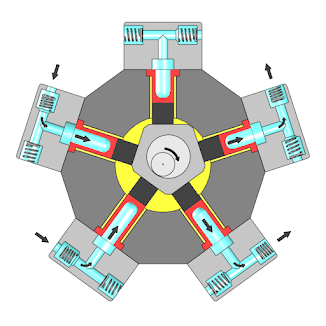

A rotary vane pump is a positive-displacement pump that

consists of vanes mounted to a rotor that rotates inside a cavity. In some

cases these vanes can have variable length and/or be tensioned to maintain

contact with the walls as the pump rotates A critical element in vane pump

design is how the vanes are pushed into contact with the pump housing, and how

the vane tips are machined at this very point. Several type of "lip"

designs are used, and the main objective is to provide a tight seal between the

inside of the housing and the vane, and at the same time to minimize wear and

metal-to-metal contact. Forcing the vane out of the rotating centre and towards

the pump housing is accomplished using spring-loaded vanes, or more

traditionally, vanes loaded hydrodynamically (via the pressurized system

fluid).

Radial piston pump -

A radial piston pump is a form of hydraulic pump. The

working pistons extend in a radial direction symmetrically around the drive

shaft, in contrast to the axial piston pump.

CLUTCH PUMPS -

A clutch pump is a small displacement gear pump equipped

with a belt-driven, electromagnetic clutch, much like that found on a car’s air

conditioner compressor. It is engaged when the operator turns on a switch

inside the truck cab. Clutch pumps are frequently used where a transmission power

take-off aperture is not provided or is not easily accessible. Common

applications include aerial bucket trucks, wreckers and hay spikes. As a

general rule clutch pumps cannot be used where pump output flows are in excess

of 15 GPM as the engine drive belt is subject to slipping under higher loads.

FEATURES

-

Small displacement pumps

Belt driven

Aerial bucket trucks, wreckers and hay spikes

Limited to 15 GPM applications

DUMP PUMPS -

Of the different types of hydraulic pumps, the dump pump is

the most recognizable. This type of pump is commonly used in dumping

applications from dump trailers to tandem axle dump trucks. The dump pump is

specifically designed for one application – dump trucks – and is not suitable

for other common trailer applications such as live floor and ejector trailers.

What separates this pump from the traditional gear pump is

its built-in pressure relief assembly and an integral three-position, three-way

directional control valve. The dump pump is unsuited for continuous-duty

applications because of its narrow, internal paths and the subsequent

likelihood of excessive heat generation.

Dump pumps are often direct mounted to the power take-off;

however, it is vital that the direct-coupled pumps be rigidly supported with an

installer-supplied bracket to the transmission case with the pump’s weight at

70 lbs. With a dump pump, either a two- or three-line installation must be

selected (two-line and three-line refer to the number of hoses used to plumb

the pump); however, a dump pump can easily be converted from a two- to

three-line installation. This is accomplished by inserting an inexpensive

sleeve into the pump’s inlet port and uncapping the return port.

Many dump bodies can function adequately with a two-line

installation if not left operating too long in neutral. When left operating in

neutral for too long however, the most common dump pump failure occurs due to

high temperatures. To prevent this failure, a three-line installation can be

selected – which also provides additional benefits.

FEATURES

-

Dump pump most recognizable

Specifically designed for dump trucks

Displacement of slightly more than six cubic inches,

pressure relief assembly and integral three-position, three-way directional

control valve

Not suited for continuous-duty applications

Often direct coupled to PTO, need installer-supplied bracket

to support

Two- and three-line installations available (two-line can be

converted to three-line)

REFUSE PUMPS

-

Pumps for refuse equipment include both dry valve and Live

Pak pumps. Both conserve fuel while in the OFF mode, but have the ability to

provide full flow when work is required. While both have designs based on that

of standard gear pumps, the dry valve and Like Pak pumps incorporate

additional, special valving.

DRY VALVE

PUMPS -

Primarily used on refuse equipment, dry valve pumps are

large displacement, front crankshaft-driven pumps. The dry valve pump

encompasses a plunger-type valve in the pump inlet port. This special

plunger-type valve restricts flow in the OFF mode and allows full flow in the

ON mode. As a result, the horsepower draw is lowered, which saves fuel when the

hydraulic system is not in use.

In the closed position, the dry valve allows just enough oil

to pass through to maintain lubrication of the pump. This oil is then returned

to the reservoir through a bleed valve and small return line. A bleed valve

that is fully functioning is critical to the life of this type of pump, as pump

failure induced by cavitation will result if the bleed valve becomes clogged by

contaminates. Muncie Power Products also offer a butterfly-style dry valve,

which eliminates the bleed valve requirement and allows for improved system

efficiency.

It’s important to note that with the dry valve, wear plates

and shaft seals differ from standard gear pumps. Trying to fit a standard gear

pump to a dry valve likely will result in premature pump failure.

How do

hydraulic pumps work?

A hydraulic pump is a mechanical device that converts

mechanical power into hydraulic energy. It generates flow with enough power to

overcome pressure induced by the load.

Advantages

of Pump -

These are

some advantages of Pump -

As there is no drive seal so there is no leakage in the

pump.

There are very less frictional losses.

The construction of the pump is Simple.

Almost no noise.

Minimum wear as compared to others.

Disadvantages

of Pump -

These are

some disadvantages of Pump -

Produce cavitation.

Corrosion.

Cannot be able to work at high speed.

Applications

of Pump -

The main

applications of the pump are -

As we already discussed Pumping Water from one place to

another place.

Aquarium and pond filtering

This is also used for Water cooling and fuel injection in

automobiles

Pumping oil or gas and operating cooling towers in the

energy industry.

Uses in waste-water recycling, pulp, and paper, chemical

industry, etc.

So this

is all about Pump, I hope you like my article, by the way, feel free to post

your doubts on the comment section I will love to answer those.

Comments

Post a Comment